OPTIMIZE SHIFTING PERFORMANCE WITH VERUS PIVOT BALL AND CLUTCH FORK KIT

Maximize the shifting capabilities of your 2006-2024 Subaru WRX with the Verus Pivot Ball and Clutch Fork Kit. Crafted to fine-tune clutch engagement and pedal responsiveness, this kit guarantees seamless and accurate gear changes. Engineered for durability and resilience, the Verus Pivot Ball and Clutch Fork Kit is the ultimate choice for drivers seeking heightened performance and reliability from their vehicle.

Kit Includes:

1x Verus Billet Clutch Fork Pivot (VERA0068A)

1x Verus Forged Clutch Fork (VERA0163A)

Enhance Your Clutch System with the Verus Billet Clutch Fork Pivot

Upgrade your vehicle's clutch system with the Verus Billet Clutch Fork Pivot, a high-performance component that complements the Verus billet clutch fork. Machined from pre-hardened stainless steel, this clutch fork pivot offers a stronger pivot point, enhancing the overall durability and performance of your clutch system.

Key Features:

-

Stronger and More Durable: Crafted from premium pre-hardened stainless steel, the Verus Billet Clutch Fork Pivot is significantly stronger than the factory unit. This increased strength ensures a more robust pivot point, providing improved longevity and reliability for your clutch system.

-

Bolt-On Operation: Upgrading your clutch system is made easy with the Verus Billet Clutch Fork Pivot. The installation process is a simple bolt-on operation, allowing you to remove the old unit and replace it with this reinforced pivot without the need for complex modifications.

-

Compatibility: Specifically designed to complement the Verus billet clutch fork, this clutch fork pivot is engineered to support pressures of up to 1,000 pounds, making it suitable for high-performance applications.

Verus Forged Clutch Fork

Material Properties, Yield Strength, and Deformation

In the below section, we’re going to do our best to give a small crash course into material properties, yield strength, deformation and stress. The content is a bit dry but is important to fully understand what is occurring to the clutch fork. Our focus will be metal material properties as that is what is used here.

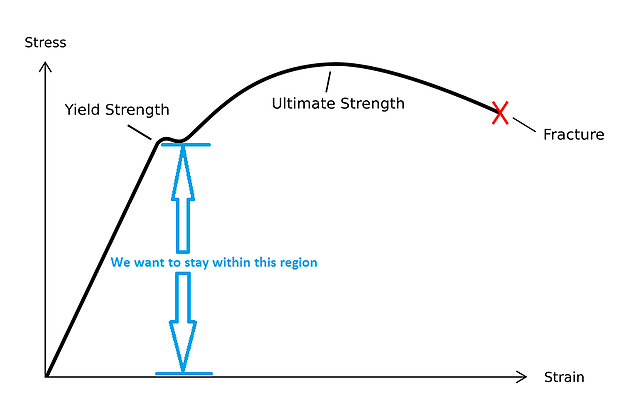

As a force is applied to a material, a stress is produced. The applied force causes the material to change shape as well, which in engineering jargon is called deformation. There are two forms of deformation a material exhibits when a force is subjected on it. Plastic deformation and elastic deformation. Elastic deformation is perfectly normal, as the force is taken off the material, the material goes back to its original shape and form. Perfect! Plastic deformation, not so much. Plastic deformation is a permanent change to the materials shape. At an atomic layer, atom bonds are breaking. The material is degrading and repetitive loading will cause a failure.

Yield strength is an indication of the maximum stress that a material can see without causing plastic deformation. So yield strength, typically given in PSI or kPa/mPa, is the numerical cross-over point from elastic (good) to plastic (bad) deformation.

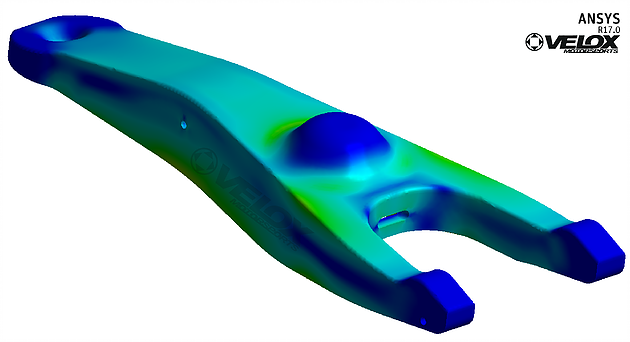

To conclude our crash course, the factory clutch forks are being stressed over yield strength and are being plastically deformed. We must create a clutch fork that keeps maximum stress under yield strength with minimal deformation.